In a previous post, we discussed that TIG welding allows the operator greater control over MIG welding. This greater control is not to imply that TIG is the superior welding method, as both methods offer similar ultimate tensile strengths as the original “weld metal,” assuming there are no weld defects in either process.

TIG welding is much slower because every “weld bead” is manually added one by one. Some welding operators refer to this as “stacking dimes.” By adding each bead individually, the operator is able to control the size and the contour of each bead. This welding process is performed with lower heat inputs, and the operator can also adjust the amperage with a foot pedal. The operator also has better control of the amount of filler material that is applied when the weld bead is formed and the amount of heat that is applied. Many operators also use gas lenses also known as “monster cups,” which allow greater shielding gas coverage, thereby reducing the chances of porosity. Gas lenses also permit the use of longer tungsten extension enabling the operator to get the electrode into tighter weld joint fit-ups. All of this control gives the ability for the operator to perform welds when material positioning is not ideal.

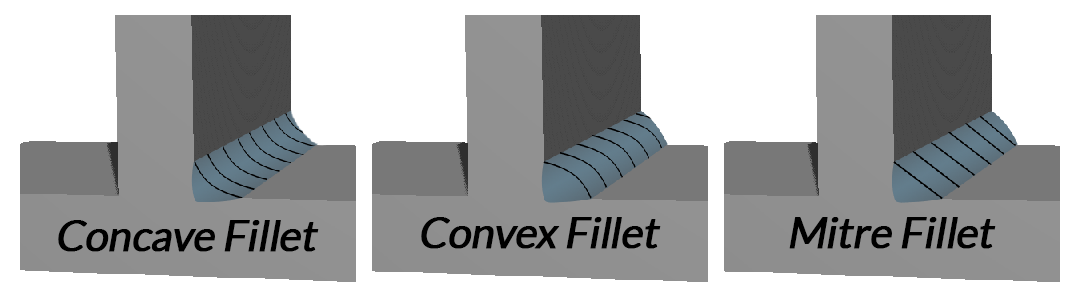

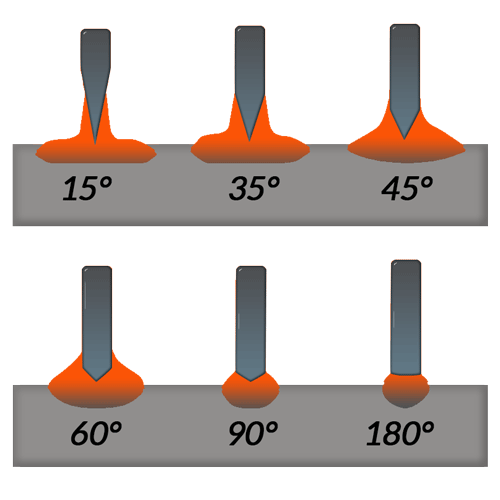

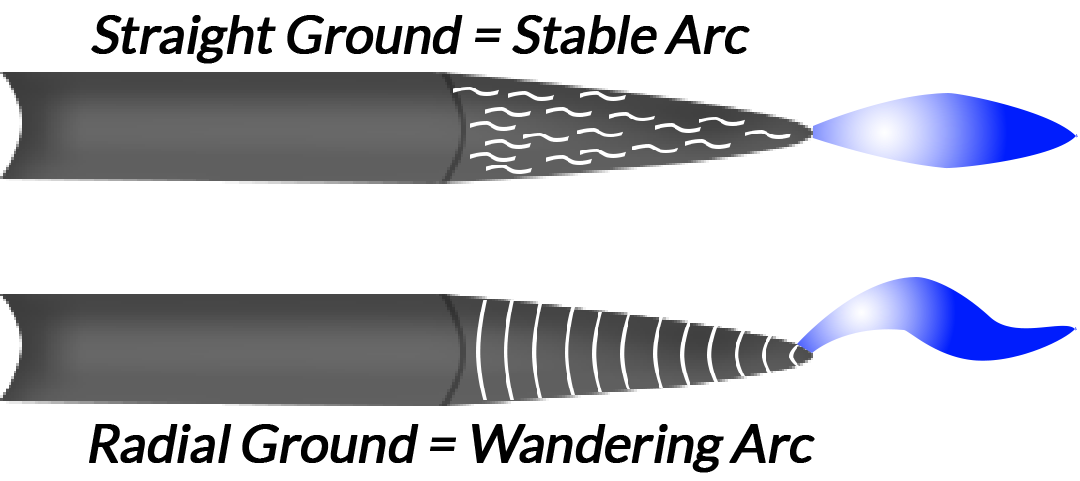

The increased control that TIG welding provides an operator comes with a cost. It is considered the most challenging welding process to learn, and it can take years to truly master. The operational control of TIG can also be its downfall as it puts the quality of the weld entirely in the hands of the operator. As an example, a very small weld with excessive concaveness may look like the “perfect weld” on the surface, but it may not have enough filler material to carry the anticipated load. The geometry of the tungsten must be considered as well when TIG welding. Grinding the tungsten to different angles affects the characteristics of the arc. Improper tungsten grinding techniques can also lead to an unstable arc.

TIG welding is susceptible to the same type of weld defects you find in MIG welding, such as lack of fusion, burn through, crater/crater cracks, undercut and porosity in the weld metal. All these defects can occur due to improper welding techniques. You also have to be concerned with tungsten inclusion and scattered tungsten inclusion when TIG welding. A tungsten inclusion is most often caused by dipping the tungsten electrode into the weld pool or touching the filler metal rod to the tungsten while welding. It can also occur when the tungsten is accidentally “stuck” to base metal and broken off. Scattered tungsten inclusion is a result of using a tungsten electrode that is too small for the amount of current being passed, causing small pieces of tungsten to be blown off into the weld pool. Tungsten inclusion can significantly reduce the strength of the weld.

This concludes our four post series on MIG and TIG welding. Please let us know if you would like us to dive deeper into this subject or any materials and fabrication topic.

We would like to credit Brett Baer from SSAB for his help on this posts technical information.