.

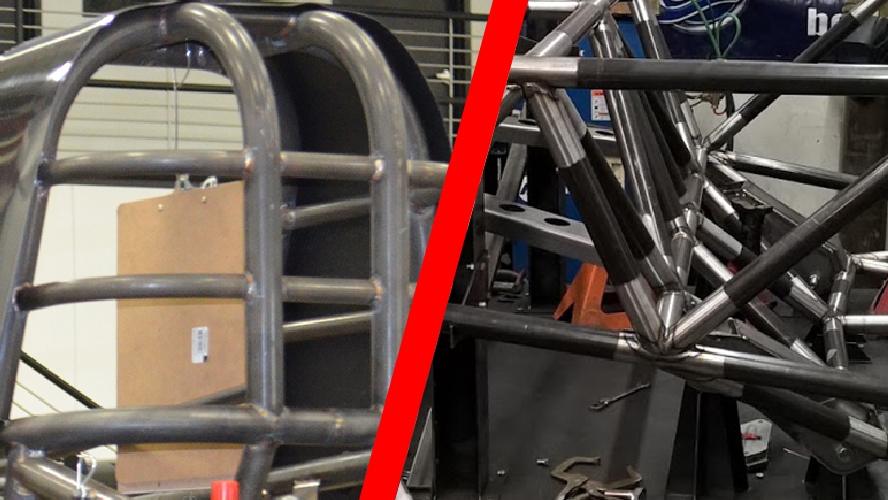

While not a very common practice in the auto racing industry, it is always recommended to remove the decarb or oxide layer from your 4130 Chrome Moly tube around the weld area. The aviation industry has been doing this since they started welding TIG welding 4130 back in the 1950's.

.

So, what is the decarb layer, anyway?

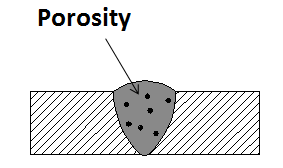

Decarburization is a type of mill scale that forms during the heat-treating process. While in the blast furnaces, the carbon molecules rise to the surface and react with the gases containing oxygen and hydrogen in the air causing oxidation on the surface of the material. This layer can vary in thickness based on allowable specifications of materials. Typically, 4130 has a minimal to zero measurable decarb. This is also a common occurrence on Mild Steel DOM tubes as well. With that said, it is best to clean / remove this layer prior to performing any fabrication.

Why is it a “best practice” to remove the decarb layer?

If the decarb layer is not removed, the weld can be contaminated. Failure to remove the decarb layer will result in “floaties” in the weld puddle. You also run the risk of undercutting the weld. This is more prevalent when the decarb layer is heavier. Removing the decarb layer will also allow the metal to wet out quicker.

How do you remove the decarb layer?

You should use a Scotch-Brite™ pad, wire brush or other abrasive to remove the black or dark decarb layer at least 1” back from the weld. The material should then be wiped down with acetone or other solvent, like Silicon Solvent 200, to remove grease and oils that may contaminate the weld. Make sure to wear nitrile gloves as the natural oils from your fingers can also contaminate the weld.

The above is recommended for a high quality and safe component. As in most projects,the better the preparation, the better the end product.